Japanese Nuclear Disaster, an Occasion to Further Nuclear Power Safety in Korea

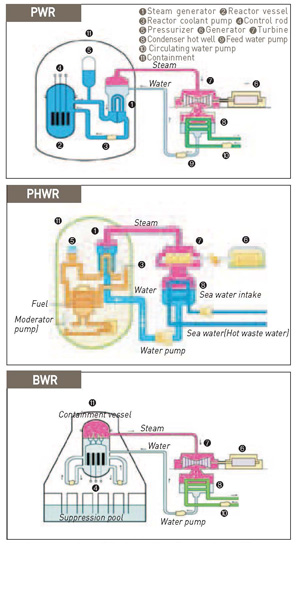

The Japanese nuclear power units are a simplified BWR design, different from the PWR/PHWR reactors in Korea

The nuclear disaster in Japan occurred on March 11 at 2:46 p.m. as a powerful 9.0-magnitude earthquake hit a seabed area east of the Miyagi Prefecture, and an ensuing dreadful tsunami with waves of more than 10 meters in height wreaked havoc on equipment and systems at the Fukushima 1st nuclear power unit.

The external flooding damaged the cooling systems of the reactors and the spent nuclear fuel storage unit that led to damage of the core part of the containment vessels and then to the release of radioactive material into the outside. The latest accident was logged as the worst nuclear disaster since the 1979 U.S. Three Mile Island disaster and the 1986Chernobyl disaster in the Soviet Union.

The difference in comparison to the previous disasters is that the latest nuclear disaster was touched off by a natural disaster and not through human error or a malfunction of the relevant nuclear power units. The tremor immediately suspended the operation of the 10 nuclear power units located near the epicenter of the quake, incapacitating the power grid of the units at the Fukushima Nuclear Power Complex, which was blamed for causing the latest nuclear disaster. On top of the disconnection from the outside power grid, the power units in question failed to properly operate with the emergency diesel-fired power generation systems. The long-term loss of power and the consequent overheating of the nuclear fuel rods led to a meltdown of the core containment vessel and a hydrogen explosion.

The failing nuclear reactors at the Fukushima Nuclear Power Complex are a boiling water reactor (BWR) model, different from Korea's pressurized water reactor (PWR) and pressurized heavy water reactor (PHWR). In the case of the BWR type, nuclear fission in the reactor core produces heat, which causes the cooling water to boil, producing steam within, which is directly used to drive a turbine for generating power. But in contrast to the BWR type, pressure in the primary coolant loop prevents the water from boiling within the PWR/PHWR reactors, because the heated water flows to a steam generator where it transfers its thermal energy to a secondary system where steam is generated and flows to turbines which, in turn, spins an electric generator. As such, the PWR/PHWR reactors limit the circulation of radioactive materials to the given spaces, making it harder to release them outside.

There is a high probability of an outside leak of radioactive materials since the steam containing radiation directly flows into the turbine, despite its cost effectiveness absent a steam generator. On the other hand, even though they demand a higher cost in equipment installation and technology development, the PWR/PHWR reactors have turned out to fare well in ensuring safety and the prevention of the spread of radioactive materials. In this context, about 71 percent of nuclear power units in operation across the globe embrace the PWR/PHWR design type.

Nuclear power units of the Korea Hydro & Nuclear Power Co. (KHNP) have applied a Defense-In-Depth (DID) concept at each stage, including its design, construction and operation. Almost every PWR type reactor owned by KHNP is constructed with five barrier walls in order to prevent any leakage of radioactive materials to the outside. Here is a look at what steps are in place to ensure the safety of nuclear power units in operation in Korea.

First, the nuclear power units in Korea are designed to ensure a stable supply of power with a separation of on-site and off-site power supply systems. In the case of station blackout (SBO) considerations, a situation that makes alternating current unavailable, batteries are not only activated to supply power, but also an additional alternative current generator is in a stand-by mode.

Second, in the case of a shutdown of all power facilities, the PWR units shift into a natural circulation and cooling mode to ensure the soundness of the core facility.

Third, there is equipment designed to eliminate hydrogen to prevent the repeat of the U.S. Three Mile Island disaster. Another passive hydrogen controlling apparatus that can be activated without the supply of power is being installed to further the safety of the core part.

Lastly, spent fuel is stored in a water pool with rods spread apart enough to prevent criticality, and it is kept inside a fuel building, separate from the reactor structure so that emergency water supply steps can be taken without the leaking of radioactive material. In a worst-case scenario, a ventilation system can be manually opened before hydrogen is accumulated, preventing hydrogen explosions.

EXTENSIVE SAFETY INSPECTION

KHNP formed a team of outside and inside experts and conducted an extensive inspection of the 21 nuclear power units in operation across the nation in reaction to the ongoing nuclear accidents in Japan. The inspection focused on the safety of the nuclear power units and emergency response readiness for serious accidents caused by tsunamis with waves of more than 10 meters in height, as was the cause of the Japanese nuclear disaster. The outcomes of the safety checks showed that there was no possibility that the prospects of earthquakes and tsunamis in Korea could threaten the safety of nuclear power units in terms of design, and chances are low that the likes of the tsunamis that hit Fukushima could lead to a serious nuclear disaster. On top of its own inspection, the KHNP will consider the results of joint comprehensive safety checks by government officials and experts and follow-up measures by the International Atomic Energy Agency (IAEA) and other international organizations following the Japanese nuclear disaster to further the safety of nuclear power units in Korea.

NUCLEAR POWER, REALITY OPTION

The Fukushima nuclear disaster could dampen the publicí»s positive response to nuclear power amid the so-called global nuclear renaissance. Some experts believe that if the current crisis is overcome wisely, a better future for the global nuclear power industry will unfurl: further ramping up the safety of nuclear facilities and the advancement of nuclear technology.

Even though the public misgivings over the leakage of radioactive material in Japan, which grabbed the headlines, is understandable, the reality is that for Korea, a nation lacking in natural resources, there is no viable alternative to nuclear power as a key power source, given the limit of new and renewable energy sources and the depletion of fossil fuels around the world.

Additionally, atomic power comes with the lowest price tag for power generation, contributing to the improvement of the lives of the nationí»s people. Figures showed that the consumer price index jumped 230 percent since 1982, but electricity charges climbed a meager 14.5 percent during the period. Nuclear power is environmentally-friendly -- nuclear power units emit about 10 grams of CO2 per 1KWh of electricity, 1/100th of the CO2 emissions of coal-fired plants. From a national energy security perspective, uranium, the fuel for nuclear power, can be found globally, compared to crude oil, limited to the Middle East and a few other areas.

Experts say that the Japanese nuclear disaster could be translated into an opportunity to dramatically upgrade disaster prevention/restoration steps, the emergence of training programs and the safety of nuclear facilities by conducting in-depth analysis of the Japanese nuclear disaster and exploring mid- and long-term measures to reinforce nuclear safety so nuclear power, the most economical, safe and realistic alternative solution, can become a safe and comfortable tool for civilization to benefit the next generation. nw

Photos on Courtesy of KHNP

3Fl, 292-47, Shindang 6-dong, Chung-gu, Seoul, Korea 100-456

Tel : 82-2-2235-6114 / Fax : 82-2-2235-0799