Samsung Wins Singapore Project

$628 million LNG terminal project puts company close to its annual overseas project target of $8.2 bln

Samsung Corporation has won a construction contract to build a liquefied natural gas terminal worth US$628 million in Singapore its first overseas contract for the year. The construction division of the company, Samsung C&T Engineering and Construction Co., is the exclusive builder for the project, commissioned by Singapore LNG Corporation Pte.

Samsung Corporation has won a construction contract to build a liquefied natural gas terminal worth US$628 million in Singapore its first overseas contract for the year. The construction division of the company, Samsung C&T Engineering and Construction Co., is the exclusive builder for the project, commissioned by Singapore LNG Corporation Pte.

An LNG terminal typically has storage tanks that collect liquefied gas from specially-equipped ships, re-gasify it and deliver it to end users through pipelines. Samsung will complete its construction project by April 2013 on reclaimed land on Jurong Island in southwest Singapore distribution capacity for the first phase will be 3 million tons per annum. The company will build two 180,000 cubic meter storage tanks and other unloading facilities.

Samsung won the contract after two rounds of fierce competition with other bidders, including a round based on price and the second on technical competence. It was given the highest score in terms of LNG terminal design capability and technological know-how. Samsung has accumulated a great deal of technical experience in the area of building low-temperature tanks, including those at the Pyeongtaek and Incheon LNG terminals (Korea) and terminal in Qatar.

Jung Gee-Chuk, Overseas Sales Divisional Chief at Samsung Corporation, said, We have secured a foothold in the world energy plant market by winning this project after a hard-fought competition. We expect many more LNG contracts to roll in as natural gas is more and more looked upon as a clean fuel, he added.

Samsung Corporation has set a goal of winning a total of $8.2 billion in overseas contracts, such as construction, civil engineering, and plant, for the year 2010. It plans to steadily increase its proportion of international revenue.

The $8.2 billion target is four times as much as it achieved in 2009. Given its brand recognition and technical expertise, in addition to the projects it has already won, including the United Arab Emirates nuclear power plant deal, however, company officials are optimistic that the goal is abundantly achievable.

In the meantime, the company completed the Incheon International Airport Bridge in 2009. The construction of the cable-stayed bridge was completed in October 2009, 52 months after starting work in July 2005.

Connecting Incheon International Airport to Songdo City, the bridge spans 21.4 kilometers (including a 12.3 km ocean section), which is a landmark in the history of Korea civil engineering achievements.

The main tower is 238.5 meters, with a center span between towers of 800 meters. It is the longest bridge in Korea and the fifth longest cable-stayed bridge in the world.

The bridge was designed to withstand earthquakes (Richter scale 7.0 and higher) and high-velocity winds (72 meters per second or more).

The ocean-side section of the bridge consists of a cable-stayed bridge (1,480 m), connecting bridge (1,778 m), and approach bridges (8,400 m).

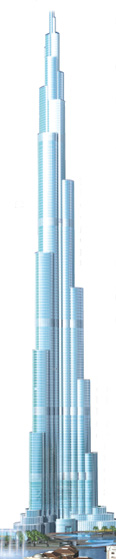

In the meantime, the opening of Burj Khalifa, formerly known as Burj Dubai, was a triumph of Samsung Corporation perspiration and inspiration. Only 34 field executives and managers were dispatched from the headquarters, and they worked closely with a total of 160 engineers from 40 countries, including Britain, Germany, and Belgium, specializing in high-rise building construction. In addition, they successfully managed up to 12,000 workers from many countries such as India and Pakistan.

The experience Samsung gained from building high-rises such as the Petronas Twin Towers (Malaysia) and Taipei 101 (Taiwan) became an important asset for the successful completion of the latest global icon in the United Arab Emirates. Built with a combination of reinforced concrete and steel framework, Burj Khalifa made use of Samsung-developed 80MPa ultra high strength concrete. The technology for the vertical high-pressure blowing system that the company used in building Taipei 101 was also employed in the Burj Khalifa construction. The system was able to pump the concrete mix up to the 156th floor, or 601 meters (1,972 ft.). The use of three satellites for GPS measurement to maintain the margin of error for verticality to within 5 millimeters was a world first.

Building the framework for a floor every three days is uniquely Samsung. Typically it takes more than a week to build a floor based on conventional formwork technology, which greatly extends construction time and multiplies costs to a considerable degree. Samsung introduced the so-called automatic formwork elevation system, which enabled the company to shorten the construction time with no sacrifice in structural stability. At the final phase of Burj Khalifa construction, Samsung set up a project to lift the spire in place using innovative technology. It involved pushing the 143 meter 430 ton spire up from inside the top of the building using hydraulic jacks.

Many technologies that Samsung employed in building the Dubai skyscraper, including hoisting technology, and the skills to manage 12,000 workers and handle all the building materials and equipment, have become a global standard for the creation of ultra high-rise buildings.

The successful completion of Burj Khalifa owes much to the concerted efforts of several Korean companies. For example, Heehoon D&G took charge of the interior design work in the observatory and the lobby, while EEW Korea, a company based in Sachon, South Gyeongssang Province, specialized in lifting the spire in place in the final phase of the construction. In addition, many other domestic companies contributed to making the world tallest building a reality by supplying high-quality fireproof boards, slip joint plumbing, wedge couplers, and steel frames.

It took only five years for Samsung Corporation to build the 828 meter (2,717-ft.) monument. Given that it had also taken five years for America 442 meter Willis Tower (formerly the Sears Tower), the Burj Khalifa construction was nothing less than a miracle.

Since April 16, 2005 when the company began building the structure up from the second basement level, after completing the foundation work the previous year, construction industry records have tumbled one after the other. In February 2007, the building surpassed the height of 110 floors held by the Willis Tower (formerly Sears Tower). In May of the same year, it broke the record for pumping concrete 452 meters up using a vertical high-pressure blowing system, outdoing the 449 meter record established by the builders of Taipei 101 (Taiwan).

On July 21, 2007, it stood 512 meters, becoming the world tallest building by topping the 508 meter Taipei 101. On September 10 of the same year, it was up to 553 meters, exceeding Moscow Ostankino Tower (540 meters), and ranking as the world highest free-standing man-made structure.

In April 2008, the company again broke the record, by pumping concrete as high as 601 meters on the 158th floor. The record-breaking march went on, by outstripping on April 8 of the same year the height of the KVLY-TV mast (628.8 meters) in North Dakota (U.S.). In September, the building became higher than the Warsaw (Poland) radio mast (646.6 meters).

Samsung employed hydraulic jacks to push the 143 meter, 430 ton spire to the top of the building, and succeeded in installing it on January 17, 2009. nw

A view of Burj Khalifa in Abu Dhabi, the tallest building in the world ,which was built by a consortium of construction companies including Samsung C&T.

3Fl, 292-47, Shindang 6-dong, Chung-gu, Seoul, Korea 100-456

Tel : 82-2-2235-6114 / Fax : 82-2-2235-0799