POSCO Sees Q3 Sales Surge

Steel maker also ready to take measures to cut carbon dioxide gas from its plants

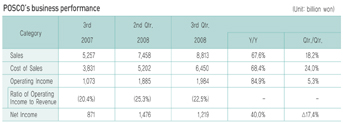

POSCO piled up a marvelous record again in the third quarter, following the record performance in the preceding quarter with its sales at 8.8 trillion won, up 67.6 percent YoY, the company announced recently.

POSCO piled up a marvelous record again in the third quarter, following the record performance in the preceding quarter with its sales at 8.8 trillion won, up 67.6 percent YoY, the company announced recently.

The sales brought the operating profit to 1.9 trillion won, up 84.9 percent YoY and net profit to 1.2 trillion won, up 40 percent YoY.

During the investor relations session held by the world's fourth largest steel-maker at the Korea Exchange in Yeouido, Seoul, Oct. 14, the company said the quarterly sales exceeded those in the preceding quarter by 18 percent and operating profit by 5.3 percent. The second quarter sales was considered the company's largest quarterly sales in its history.

The Q3 sales increase has been owed to increases in the prices of steel products and cuts in the prices of iron ores, officials of the steel maker explained. The depreciation of the Korean currency vis-vis U.S. dollar also boosted the sales and profit figures,

while the import prices of iron ores remained the same due to a long-term nature of the contract, they said.

while the import prices of iron ores remained the same due to a long-term nature of the contract, they said.

Vice President Lee Dong-hee said the stainless steel sector recovered its losses last year and made profits.

In the meantime, POSCO braces for tougher carbon rules by taking up new technology to reduce the emissions of deadly carbon dioxide gas from its steel making facilities, coming to about 10 percent of the toxic gas emitted in the country.

Korea, Asia's 4th largest economy, is coming under pressure to reduce the emission of the harmful gas under Kyoto Protocol on CO2 as poorer nations want rich nations to take the lead in cutting down the dangerous gas emissions around the world to help suspend climate warming, which is blamed by increased emission of carbon dioxide from industrial plants around the world.

POSCO's strategy to reduce the emission of the deadly gas from its steel making plants is to use FINEX steel-making technology, which the steel maker developed in partnership with Siemens of Germany as an alternative form of steel making to the old blast furnaces.

FINEX cuts the emission of the toxic gas during the processes of steel-making and allows the use of cheaper raw materials such as ores fines and non-coking coal, a steel-making system which is god-send in this time of high raw material prices, including those of iron ores and coal.

Senior Exec. Vice President Hwang Eun-yeon said the steel-maker, now ranked the 4th largest in the world, had not much choice to reduce the gas except to improve its steel-making technology to boost the productive effectiveness of steel production plants.

FINEX is helping the steel producer to cut costs by lowering input costs by 10 percent on average, he said. Over the past three years, the cost savings due to FINEX came to 3 trillion won boosting profits for the company. POSCO will be able to cut the toxic gas emission by 4 percent over the next four years. The steel producer will use FINEX technology for its projected steel plants in India, costing some $1.2 billion and for its steel plant in Vietnam when it is built at the cost of $5 billion.

Citigroup estimates FINEX saves POSCO about 8 percent on raw materials and 18 percent on capacity expansion compared with blast furnace peers in China and Japan.

The need for emission cuts is urgent for many steel producers because the sector accounts for about 4 percent of total world carbon dioxide emissions. Environmentalists are also urging greater efficiencies in the sector.

IISI backs a global sectoral approach in tackling emissions instead of cap-and-trade systems. POSCO's move is in line with IISI's position, which highlights the need for new technology to reduce carbon emission and raising energy efficiency. nw

Chmn. Lee Ku-taek of POSCO.

3Fl, 292-47, Shindang 6-dong, Chung-gu, Seoul, Korea 100-456

Tel : 82-2-2235-6114 / Fax : 82-2-2235-0799