Hankook to Beef Up

its Presence Abroad

Strives to become a global machine tools powerhouse with its credibility and technical prowess

Hankook Machine Tools is a driving force behind the evolution of the Korean machine tool industry into a global powerhouse.

Hankook Machine Tools is a driving force behind the evolution of the Korean machine tool industry into a global powerhouse.

Established in 1969, Hankook Machine Tools is synonymous with the domestic machine tools industry. Hankook has been at the center of the development of the Korean machine tools industry with the large and heavy-duty equipment the company has developed with its own technology for the past 40 years under the catchphrase "Challenge & Creation."In fact, Korea's steel, shipbuilding, automotive and semiconductor industries, which have emerged as being among the world's strongest production centers, have formed a solid foundation for the advancement of the domestic machine tools industry.

Research & Development

Hankook is expanding its efforts to explore new horizons and realize future aspirations in order to meet its customers'needs and expectations. Its continuous development of differentiated products tailored to its customers'needs has led to enhancing its credibility and achieving technical prowess.

As a result, it has built up a business network with such major users as POSCO, Hyundai Steel, Dongbu Steel, Hyundai Heavy Industry, STX Corporation, Korea Railroad Corporation, and others.

As a result, it has built up a business network with such major users as POSCO, Hyundai Steel, Dongbu Steel, Hyundai Heavy Industry, STX Corporation, Korea Railroad Corporation, and others.

Hankook is striving to beef up its global presence with the goal of developing itself into a world-class machine tools powerhouse by cashing in on its success in the Korean market.

The company now has offices in Europe, the United States, China, India and Singapore, and is expanding its reach with a sales network in over 30 countries in the Middle East, Southeast Asia, Eastern Europe, Africa and other newly emerging markets.

Hankook is focusing on investment in R&D and technical innovation in a bid to place itself in the forefront of future technology, recognizing the fact that a thorough knowledge and understanding of its customers'needs is essential for its continued success.

Hankook's R&D staffs represent 30 percent of its employees and make the most of its wide range of engineering

experience in offering optimum technological solutions. Based on this, Hankook is making the development of new technology and enhancing the quality of its machine tools a top priority.

experience in offering optimum technological solutions. Based on this, Hankook is making the development of new technology and enhancing the quality of its machine tools a top priority.

Hankook is making all-out efforts to ensure customer satisfaction, one of its corporate values. To this end, the company has implemented the ISO9001 quality management system designed to strictly manage every step in the manufacturing process from engineering and production to sales and services.

The company produces top-class products in modern facilities employing highly skilled engineers and first-rate workmanship with precision and accuracy. Hankook has built up one-stop solutions for producing materials and processes on its own, as opposed to the outsourcing done by many machinery builders. This strict control over major components allows Hankook to maximize its customers'satisfaction for the quality of machines and their delivery.

Located at the Korean National Industrial Complex in Changwon, the mecca of the domestic machine tools industry,

Hankook Machine Tools headquarters, manufacturing workshops and R&D center have the latest facilities and systems to meet its customers'needs.

Hankook Machine Tools headquarters, manufacturing workshops and R&D center have the latest facilities and systems to meet its customers'needs.

Hankook has always been pulling out all the stops to enhance its technological competitiveness according to the trends of the time with a sprit of continuous innovation and challenge.

Its technological development began in the 1960s through a joint venture with Dainichi Kinzoku Kogyo of Japan for the production of a gear driven conventional manual lathe. This was a watershed in the development of the Korean machine tools industry, since it was recognized by the government as a "specialized lathe maker."Since the 1980s, Hankook Machine Tools has concentrated on the development of large and heavy-duty machine tools, and now manufactures some of the world's finest large sized CNC machines.

PRODUCTS

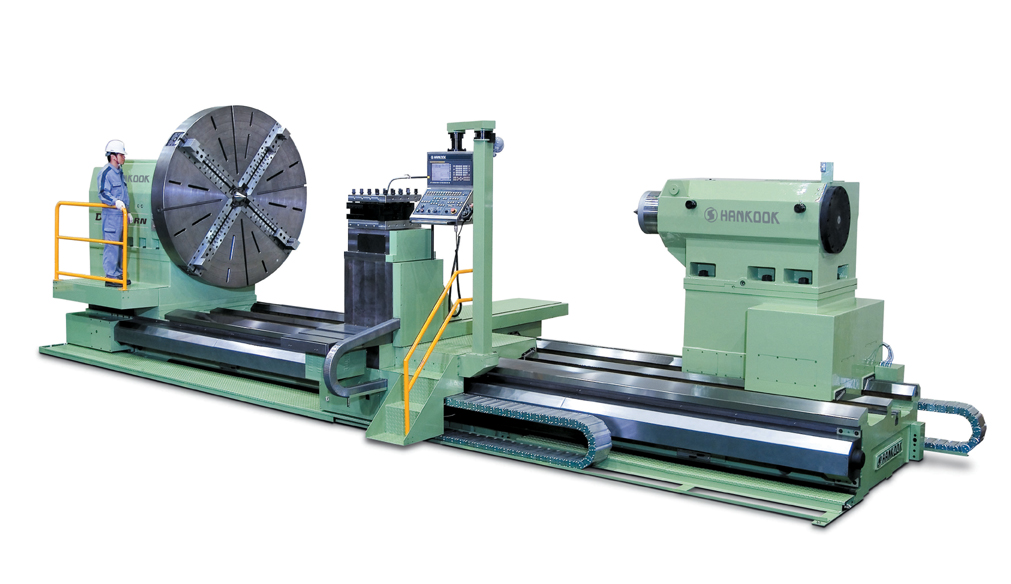

In an effort to meet its customers'demands, Hankook has provided high quality machines for various production requirements, including a large range of CNC vertical lathes, CNC horizontal lathes, horizontal manual lathes, heavy-duty CNC roll lathes, and CNC portal type machining centers to the global market.

The CNC vertical type lathes VTB and VTC cover single and double column types, elevating cross rail types with turning diameters of 1 meter to 8 meters.

These VTLs offer high precision with heavy duty capabilities required by such products as railway wheels, large valves, shipyard material, aircraft parts, construction equipment parts and a wide range of other heavy industrial components.

The range complies with CE Mark certification, and a growing number of references in Europe, the United States, the Middle East, Africa and Russia are adding to Hankook's range of customers worldwide.

Hankook manufactures standard products ranging from medium-sized to super-sized horizontal lathes with a distance between the centers ranging from 1 meter to 16 meters and swing over a bed from 500 mm to 3 meters. These powerful lathes are a major force for turning many large parts such as large shafts for wind power generation and gas turbines for power plants.

Hankook is Korea's only manufacturer of roll lathes with the R-Series having capacities from 10 tons to 100 tons. Roll lathes, offering turning capacities for up to 6-meter-long rolls for plate and section rolling mills, have been delivered to POSCO, Dongkuk Steel and Hyundai Steel. Its technology offers a level of performance and reliability much appreciated by its customers in these tough manufacturing environments. Recent deliveries of the machines to Maanshan Steel in China and Sail Steel, a government project company in Bhilai, India, have been well received.

Portal type CNC machining center

With its ever-expanding technology and facilities, Hankook manufactures fixed and elevating cross-rail bridge type machining centers. Its PMC and PME Models offer Distance Between Columns from 2.1 meters to 5.5 meters; table lengths from 3 meters to 12 meters; and table loading from 10 tons to 150 tons.

For meeting various applications Hankook offers many different types of spindle heads and high-speed spindles as well as the Automatic Tool Changer (ATC), Automatic Attachment Changer (AAC) and the Automatic Pallet Changer (APC), which are instrumental in achieving the highest productivity.?

Its portal-type machining center is well suited for applications such as large ship engine components, automobile frames, large machine tools, aircraft parts, large heavy duty machining and mold machining. A special E-Rail planer, developed by Hankook, provides ideal and optimum performance for the machining of elevator rails.

Hankook is developing and producing lapping and polishing machines to meet the demand for super precision in the IT industry. The products cover plate diameters of 1,100 mm to 3,200 mm graded 16B to 48B. This equipment is concerned with the production of such items as silicon wafers and glass and large range optical parts requiring a super-precise process by semiconductor and optical parts makers such as LG-Siltron. nw

Ryu Hung-mock, CEO of Hankook Machine Tools and concurrently chairman of the Korea Machine Tool Manufacturers'Association.

DYNATURN, produced by Hankook Machine Tools, is tough enough for machining Hard Rolls'for steel mills.

KOMMA Chairman Ryu meeting with NewsWorld President-Publisher Elizabeth M. Oh.

3Fl, 292-47, Shindang 6-dong, Chung-gu, Seoul, Korea 100-456

Tel : 82-2-2235-6114 / Fax : 82-2-2235-0799