Incheon Bridge Shaping

Up as a Landmark

46 percent completion of structure emerging as one of Korea's longest bridges

The Incheon Bridge has unveiled its splendor, achieving 46% completion of the structure against overall construction schedule by finishing the foundation work less than 700 days after the ground-breaking, which will become the longest bridge in Korea and will be among the five longest bridges of its kind in the world. In particular, the most challenging job of driving as many as 630 piles into the seabed has been successfully accomplished, curtailing a period of the foundation work by 3 months against the original plan. It is also anticipated that adding the largest equipment in history of the Korean bridge construction will result in accelerating the current pace of the construction progress.

The Incheon Bridge has unveiled its splendor, achieving 46% completion of the structure against overall construction schedule by finishing the foundation work less than 700 days after the ground-breaking, which will become the longest bridge in Korea and will be among the five longest bridges of its kind in the world. In particular, the most challenging job of driving as many as 630 piles into the seabed has been successfully accomplished, curtailing a period of the foundation work by 3 months against the original plan. It is also anticipated that adding the largest equipment in history of the Korean bridge construction will result in accelerating the current pace of the construction progress.

This outstanding progress rate has been displayed as a result of executing the Fast Track construction method which enables the design to synchronize with the construction. In addition, the Incheon Bridge project has adopted a number of advanced construction methods into implementation of the project,

even being named as 'a hotbed for modern technologies in bridge construction's and it made a signification contribution to elevate the working efficiency on site along with drastic measures taken to engage the global-scale equipment in operation.

even being named as 'a hotbed for modern technologies in bridge construction's and it made a signification contribution to elevate the working efficiency on site along with drastic measures taken to engage the global-scale equipment in operation.

The world-scale equipment, the Launching Gantry allowing the automatic installation of huge girders on piers and the Carrier are on standby with a high expectation to bring substantial advantages to the project execution in terms of expediting the progress of the rest construction work.

The Incheon Bridge due to open in October, 2009 is a cable-stayed bridge with a total length of 12.34km, supporting three lanes in each direction across the span. After completion, the bridge will become the longest one in Korea and will stand as the 5th longest bridge in the world with its main span being 800m. Also the Incheon Bridge was highly evaluated by Construction News, a British professional construction journal, which had selected the Incheon Bridge as one of the World's Top 10 Construction Wonders.

Construction Progress

Construction Progress

The current progress rate represents 46% following the completion of the foundation work classified as one of the three bridge construction areas with Superstructure and Substructure works. The Incheon Bridge is made up of a cable-stayed bridge which the pylons locate, viaducts that will link the bridge with inland areas of Yeongjong Island and Songdo (island) respectively, and approaches connecting a cable-stayed bridge with viaducts.

The foundation work means the work for driving piles into the ground (or seabed) in order to make the bridge sustainable on the ground, which represents the area below the water in general. (The piles above the water applies to the level of Substructure works, and the Girder installation belongs to the level of Superstructure works) And the Incheon Bridge has finished its foundation work recently by installing as many as 630 piles (with 3 meters in diameter) in the middle of the sea.

The pylons for the cable-stayed bridge are under construction after completion of the foundation work, and they will be completed in May 2008. Currently, the factories in Korea and China are manufacturing the girders to be installed on the cable-stayed bridge, aiming to commence the installation work on the ground from the 2007 end.

After the launching ceremony of the first viaduct girder, which celebrated the setoff of lifting a massive 50-meter girder weighing 1,400 tons on to the viaduct piers, the installation of viaduct girders is currently in full swing with putting 3,000 tons of the huge crane to use. The Launching Gantry and the Carrier has been supplied to the work site for the sake of precise and speedy installation of girders manufactured on land, and they are contributed towards not only facilitating more accurate works but also bringing the benefit of curtailing a period of overall construction.

Foundation and substructure works for the approach bridges connecting the cable-stayed bridge with viaducts have been completed as well.

Girders are being manufactured and are set to be fabricated on the ground. Newly added Derrick crane is expected to speed up the fabrication process of the approach girders.

Girders are being manufactured and are set to be fabricated on the ground. Newly added Derrick crane is expected to speed up the fabrication process of the approach girders.

MOST CHALLENGING

The Incheon Bridge is to build an expressway more than 12 km long and the 230-meter pylons as high as the 63-story building over the sea so that it can be referred to as the most challenging construction work in Korean history. Being more susceptible to climate changes, the offshore works generally lack consistency in the construction process, especially during winter time and rainy spells in summer. These offshore works also require more time and costs than those onshore due to safety requirements under exceptional working environments.

In addition, most materials have been manufactured previously in onshore fabrication yard in order to reduce the time required for the construction and to make sure to get overall works done more precisely. It is inevitable to have large-scale machines and equipment involved in transporting all kinds of heavy materials including the girders with 50 meters in length and 1,400 tons in weight from onshore to offshore.

The pylons of the cable-stayed bridge and the 800-meter main span accentuate the value of the Incheon Bridge by means of integrating the modern technologies for the bridge construction. As even single error will not be tolerated in the concrete works for the reverse Y-shape pylons as high as 63-story building, an automatic-ascending cast system has been introduced for the benefit of accuracy and safety for the first time in Korea.

HIGH-TECHNOLOGIES.

The Fast Track Construction Method: This method is to allow the design to synchronize with the construction, enabling the construction period to be curtailed by way of concurrent execution of works in different stages throughout the construction process involving planning, design, purchasing, and construction. It is predicted to bring about a result to shorten a construction period by 19 months.

"How will the CSB pylons with same height as the 63 story building be constructed?"The major challenges are how to materialize the moderately-curved and reverse Y-shape pylons and to guarantee the safety for workers whose jobs are generally carried out up in the air. In this sense, the automatic-ascending cast system has been introduced for the first time in Korea as the best solution to the said challenges. It provides the means of having the concrete jobs for high-rise buildings implemented in more precise and safe manner as well as intensifying the functions focused on working offshore against potential strong winds.

"How will the CSB pylons with same height as the 63 story building be constructed?"The major challenges are how to materialize the moderately-curved and reverse Y-shape pylons and to guarantee the safety for workers whose jobs are generally carried out up in the air. In this sense, the automatic-ascending cast system has been introduced for the first time in Korea as the best solution to the said challenges. It provides the means of having the concrete jobs for high-rise buildings implemented in more precise and safe manner as well as intensifying the functions focused on working offshore against potential strong winds.

An exhibition centre for the large-scale offshore equipment: The biggest 3,000-ton crane, the global-scale Launching Gantry, and the Carrier have been introduced in the project. Considering frequent requirements to transport massive and heavy materials between onshore fabrication yard and offshore work site, it is necessarily demanded to put such kinds of special equipment in place. The Floating crane currently in operation for the Incheon Bridge weighs 3,000 tones and is equipped with a capability to transport materials up to 82.3 meters high. The Launching Gantry and the carrier will function to put the inland-manufactured viaduct girders (50 meters in length and 1,400 tones in weight) on their destinations, the piers safe and sound.

About the Construction Project

Having been funded as much as 1.5914 trillion won(US$ 1.6billion), the Incheon Bridge whose construction is be completed in October, 2009 is a cable-stayed bridge with a total length of 12.3 kilometers (supporting three lanes in each direction across the span and 33.4 meters wide), connecting Songdo International city and the Incheon International airport. The Incheon Bridge was selected as one of the worlds's top 10 Construction Wonders in 2005 by Construction News, a British professional construction journal, and currently represents 46% of construction progress. Incheon Bridge Co.,Ltd., the concessionaire of the Incheon Bridge project was established by AMEC, a UK-based multinational development company in association with domestic and international financial investors. nw

Kim Soo-hong, CEO of Incheon Bridge Co., a concessionaire of the Incheon Bridge project, established in 1999 as a joint venture between AMEC and Incheon City.

The construction process of the Incheon Bridge is moving forward without a hitch.

The Incheon Bridge project has adopted a number of advanced construction methods into implementation of the project, even being named as 'a hotbed for modern technologies in bridge construction.'

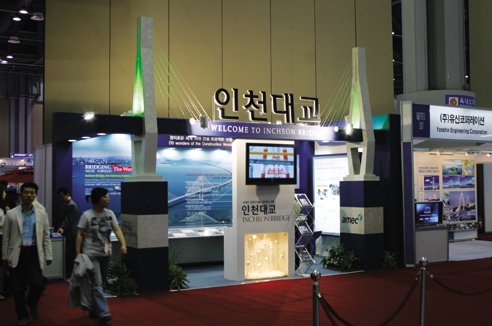

A booth on the Incheon Bridge, set up by Incheon Bridge Co. during ROTREX 2007.

3Fl, 292-47, Shindang 6-dong, Chung-gu, Seoul, Korea 100-456

Tel : 82-2-2235-6114 / Fax : 82-2-2235-0799