A Giant Steel

Network

Dongkuk Steel on way to be global steel giant with plants in China, Brazil

This will be the initial year for Dongkuk Steel to become a global steelmaker with the work to build Ceara Steel in Brazil to be in full swing.

This will be the initial year for Dongkuk Steel to become a global steelmaker with the work to build Ceara Steel in Brazil to be in full swing.

The work, which started in 2005, has been related to the preparation of grounds and the construction is to be launched in full from this year for the steel plant projected to turn out 1.5 million tons of slab annually in a three-way joint venture with CVRD of Brazil, Italy's Danieli and Dongkuk Steel.

Dongkuk Steel's new plant for steel plates to be built from this year is a part of Dongkuk's plan for securing global competitive edge that cannot be left out.

Steel plate products will spur the development of steel plates in conjunction with the Dangjin steel plant. Dongkuk will also exert its effort to induce blast furnace technologies through the expansion of alliance with JFE Steel of Japan forged last year. Dongkuk will acquire the construction technology for Dangjin plant and the technologies to produce high-grade steel plates such as TMCP.

When iron mold and slabs produced in the Brazilian plant are linked with Dangin's new steel plant, Dongkuk Steel will have an integrated steel plate production system. This means that raw material will be produced in Brazil and products will be produced in Korea where the steel market is vibrant, creating a global production system unique in the world, which will be further progressed to make Dongkuk Steel a dominant steel plate maker in the world when JFE Steel's support is added.

When iron mold and slabs produced in the Brazilian plant are linked with Dangin's new steel plant, Dongkuk Steel will have an integrated steel plate production system. This means that raw material will be produced in Brazil and products will be produced in Korea where the steel market is vibrant, creating a global production system unique in the world, which will be further progressed to make Dongkuk Steel a dominant steel plate maker in the world when JFE Steel's support is added.

Dongkuk Steel will be able to launch its effort to further enhance its global competitive edge by making steel rod and sections high value-added. The preparation for high-grade and various sizes of steel sections and enhancing marketing plan for large-size reinforcing rods have been completed last year, putting the company in a strong position to expand its markets.

The completion of construction of the company's exclusive wharfs in Pohang and Incheon last year will also help double the Dongkuk Steel's competitive edge.

The company has also launched the training program for its workforce under the M100 Project designed to select 30 employees for MBA education annually and the use of a pool of overseas personnel. The company is also set to make its structure strong able to cope with any changes in business environment through the management reform system launched last year, which ultimately will make the entire company's resources organized to be customer-centered so that the company will be able to win over any competitors in the areas of steel plates, steel rods and steel sections under the strategy.

The company has also launched the training program for its workforce under the M100 Project designed to select 30 employees for MBA education annually and the use of a pool of overseas personnel. The company is also set to make its structure strong able to cope with any changes in business environment through the management reform system launched last year, which ultimately will make the entire company's resources organized to be customer-centered so that the company will be able to win over any competitors in the areas of steel plates, steel rods and steel sections under the strategy.

The Dangjin steel plant with construction to begin this year needs JFE Steel? cooperation to make Dongkuk Steel strong in the business of steel plates. Dongkuk Steel decided to build a high-grade steel plate production system in September last year in cooperation with JFE Steel when the Dangjin plant is completed.

JFE Steel has agreed to provide technologies for the construction of the Dangjin steel plate plant,

especially those for the production of steel plates and support for stable operation of the new plant in early stages of operation. Dongkuk Steel and JFE Steel, in return, agreed to provide slabs on long-term basis and purchase the product.

especially those for the production of steel plates and support for stable operation of the new plant in early stages of operation. Dongkuk Steel and JFE Steel, in return, agreed to provide slabs on long-term basis and purchase the product.

For long-term expansion of the tie-up, the two steelmakers have also agreed to set up a strategy committee to discuss the two companies business strategies to reinforce the cooperation.

The two partners have agreed to expand their alliance to upgrade the steel plates to be produced by the Dangjin plant and stabilize its operation in the early stages and segregate its products from those of Chinese steelmakers by upgrading the quality of steel plates and explore new markets with the competitive strength that Dongkuk Steel gained and also maximize its corporate value as well.

The Dangjin plant is targeted to be launched in 2009 at the cost of 760 billion won. Dongkuk Steel has become the first Korean steelmaker to build a steel plant in Brazil, which will turn out 1.7 million tons of iron mold and 1.5 million tons of slabs annually equipped with new steel production technologies.

Work began in 2005 and so far completed the grounds for the plant last year. When completed in 2009, 1 million tons of slabs will be shipped to Korea and turned into high-grade steel plates to be used by shipyards and other industries in Korea.

Ceara Steel will get iron ores from the CVRD in Brazil and produce direct reduced iron totaling 1.7 million tons, which will be made into iron molds used to produce 1.5 million tons of slabs annually at the plant.

The direct reduced iron production process makes convexity steel with more than 90 percent iron content(Fe) by melting pellets and reduced iron in an electric-furnace to produce highly pure and high-grade iron mold.

The Ceara Steel is a joint venture put together by a world-renowned raw material supplier, facility supplier, steelmaker and financial companies.

The CVRD will take charge of supplying all the requirement of iron ores as the largest iron ores supplier in the world and facilities to be supplied by Danieli of Italy,

which boasts the highest steel production technology of its steel plant.

which boasts the highest steel production technology of its steel plant.

Dongkuk Steel, being ranked as one of the five largest steel plate makers in the world, will not only oversee the management of Ceara Steel, but also be a stable consumer of its products, holding the largest decision-making rights among the three partners.

Dongkuk Steel has also been actively engaged in the steel business in China through its affiliate Union Steel, which advanced into China's steel market by producing and marketing cold-rolled steel, lead alloy steel plates and color steel plates at its plant in Jiangsu Province in China from 1997, which is able to produce 1.5 million tons of steel products altogether annually. The company has successfully led the Korean steel industry's advancement into China, which has become the largest steel market in the world lately, in a bid to corner China? cold-rolled and lead alloy steel plate market as early as possible with Korea's steel market limited.The Dangjin plant is to be built on a site as large as 208,000 pyeong with a total investment of 760 billion won, 700 billion on machinery equipment and 160 billion won buildings and is able to produce 1.5 million tons of steel plates annually, half of them general steel and another half TMCP. Dongkuk Steel signed an MOU with JFE Steel of Japan to strengthen their alliance Sept. 25. In December, 2008, an exclusive wharf for the steel plant will be completed to handle to up to 50,000- ton carrier and in August, 2009,

the construction of the projected steel plant will be completed. Its full operation will begin in 2012.

the construction of the projected steel plant will be completed. Its full operation will begin in 2012.

Based on the alliance with JFE Steel forged on Sept. 25, 2006, the two steelmakers agreed to hold stakes in each other, JFE as much as 15 percent of stakes in Dongkuk, while Dongkuk will invest as much as 10 billion yen in JFE Steel. JFE will also provide technologies needed to build the Dangjin Steel plant including those to produce high-grade steel plates. Dongkuk Steel will continue to buy JFE Steel? slabs and JFE Steel will supply slabs to Dongkuk Steel continuously and stably.

Work on Ceara Steel began in December, 2005, followed by the launch of a legal investment entity in Brazil in March, 2006. Construction is scheduled to start in earnest this year with the completion set for the first half of 2008 and test operation. The plant will start commercial production in January, 2009. nw

Chairman Chang Sei-joo of Dongkuk Steel Mill Co.

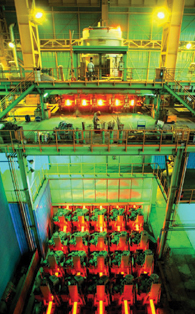

Chairman Chang Sei-joo of Dongkuk Steel, right, shakes hands with President Hajime Bada, President of JFE Steel in Japan on Sept. 26 last year in Seoul after signing the alliance agreement.(photos from above) An aerial view of Dongkuk Steel Pohang Plant.; Pohang plant? steel section production facility.; A view of steel plate production facility at the Pohang plant.

3Fl, 292-47, Shindang 6-dong, Chung-gu, Seoul, Korea 100-456

Tel : 82-2-2235-6114 / Fax : 82-2-2235-0799